Pumps

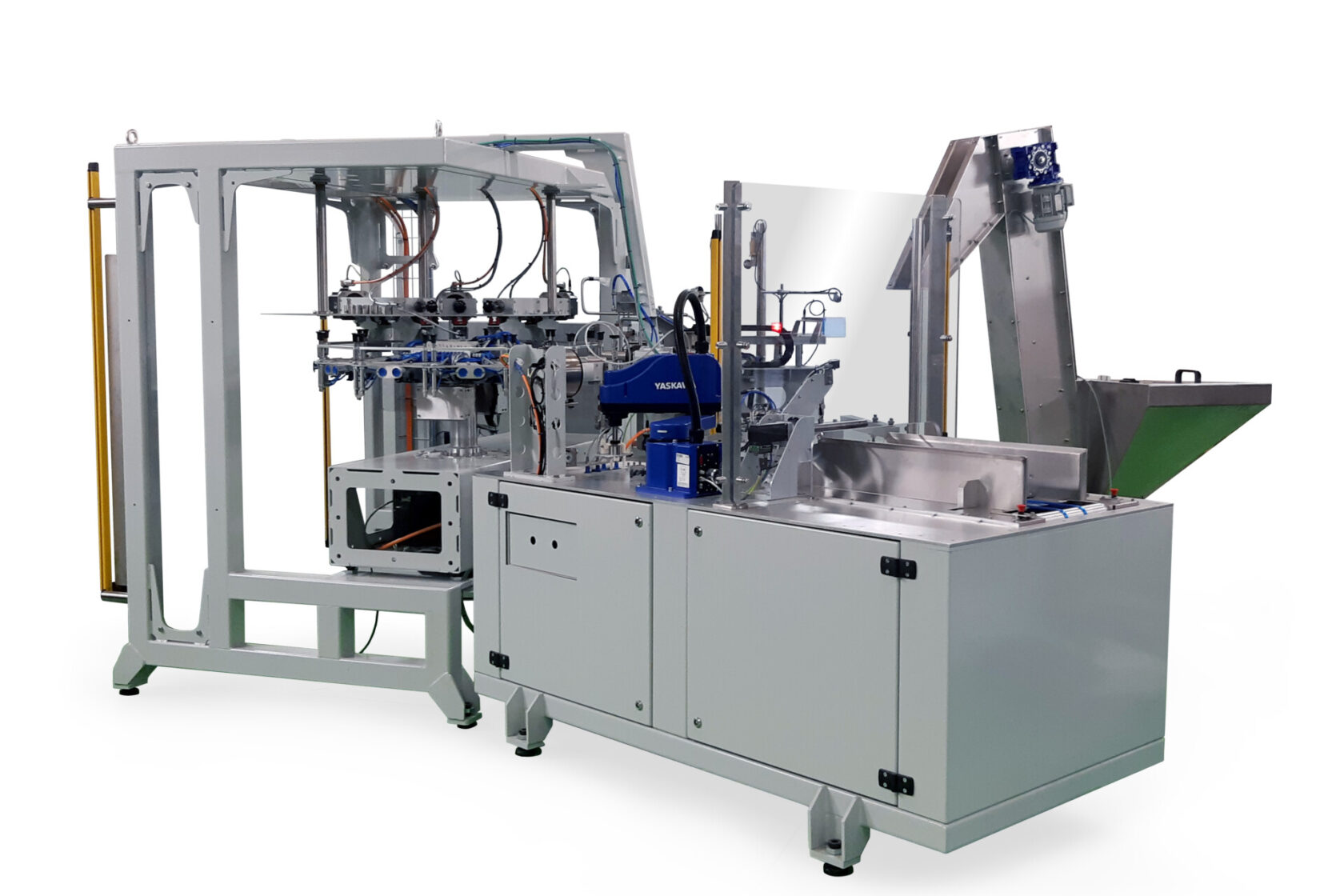

Lobe pump

A lobe pump is a positive displacement pump that uses rotating lobes to move fluids.

Key features:

- Hygienic Design: Ideal for sanitary applications, metals seals

- Versatility: Handles very low to high-viscosity fluids and with non abrasive solid parts.

- Gentle Handling: Provides smooth, non-pulsating flow. Good for Hot fill, cold fill or refrigerated filling

Applications

- Food and Beverage: Dairy, syrups, jams, yogurt, fruit pure.

- Pharmaceuticals: Sensitive products.

- Cosmetics: Creams and lotions.

- Chemicals: Low to high viscous products and shear-sensitive fluids.

Advantages

- Continuous flow pumps: good for dosing large volume containers

- Easy to Clean: Meets strict hygiene standards, with CIP (Clean-in-Place) systems

- Efficient: Consistent flow rates.

Disadvantages

- Requires CIP

- Requires priming + needs infeed pressure

- Cost: Higher initial investment.

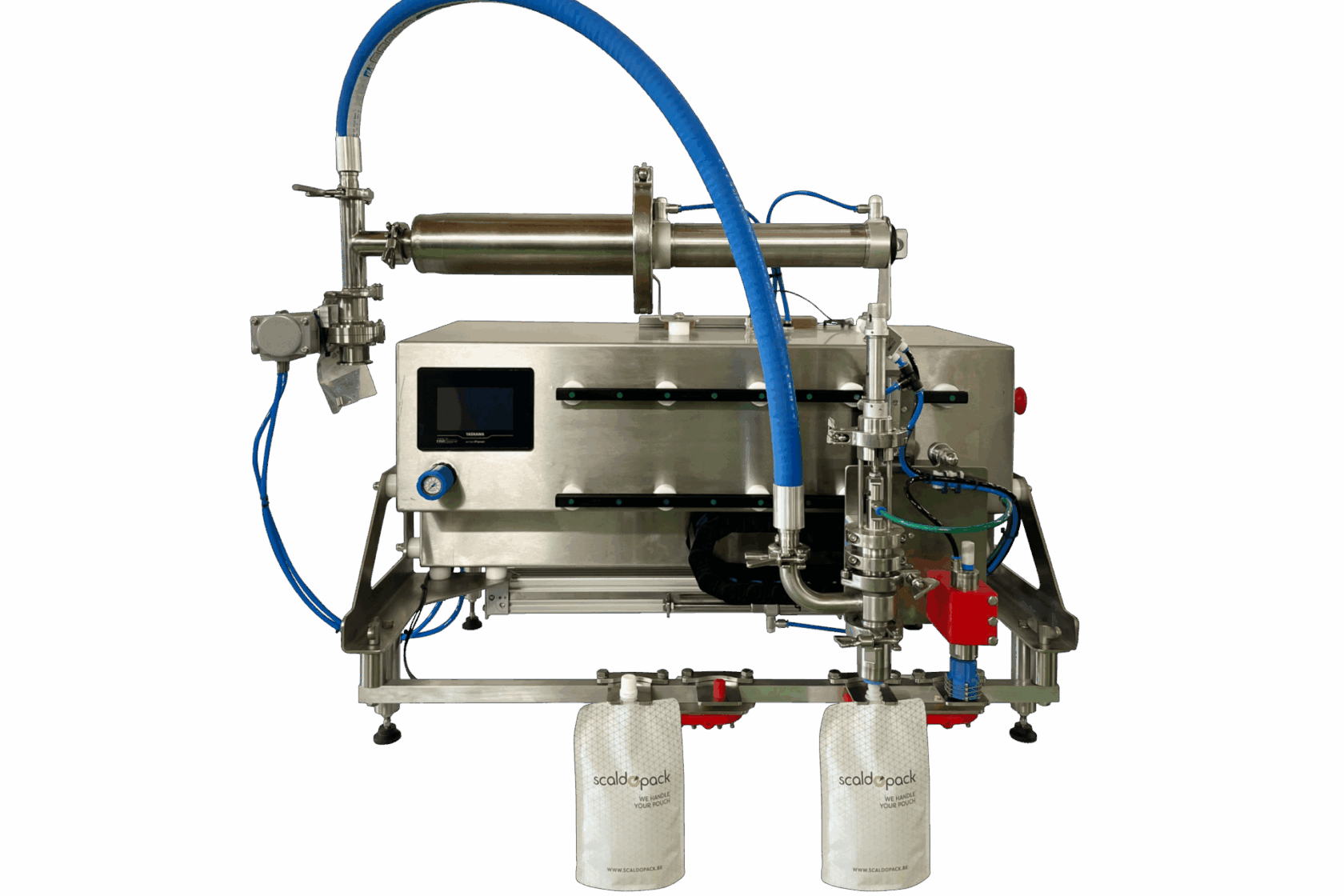

Piston pump

A piston pump is a type of positive displacement pump that uses a piston to move fluids, offering high precision and pressure capability.

Key features:

- Positive Displacement: Traps and displaces fluid.

- High Pressure: Effective for high-pressure applications.

- Precision: Accurate dosing and control.

- Servo-Controlled: Reliable, self-priming, and operates directly from IBCs or other product vessels.

- Manual Cleaning: Scaldopack pumps allow tool-free manual disassembly for daily cleaning and changing of seals.

Applications

- Food: Syrups, sauces, juices, milk, yogurt, broths, tea, etc.

- Chemicals: Low to high viscous products

Advantages

- High Pressure: Handles high viscous products and can generate high dosing pressures.

- Precise Control: Accurate dosing.

- Self-Priming: No buffer hopper needed.

- Easy Cleaning: Manual disassembly without tools.

Disadvantages

- Maintenance: For high level of sanitary application daily disabling and cleaning is required.

Centrifugal pump

An affordable solution to move fluids by converting rotational kinetic energy to hydrodynamic energy.

Key features:

- Hygienic Design: Stainless steel for sanitary use.

- High Flow Rates: Efficient for large volumes.

- Continuous Flow: Steady, non-pulsating flow.

Applications

- Beverages: Juice, milk, soft drinks.

- Dairy: Milk, hot ghee

- Brewing: Beer and wort transfer.

- Food Ingredients: Oils, syrups, sauces.

- Technical products: low to medium viscosity up to 300 cps.

Advantages

- Continuous flow pumps: good for dosing large volume containers

- Efficient: Ideal for low to medium-viscosity fluids.

- Easy Cleaning: Compatible with closed loop cleaning CIP systems.

- Cost-Effective: Lower initial cost and easy maintenance.

Disadvantages

- High Shear: Can damage shear-sensitive products.

- Limited Viscosity Handling: Not suitable for fluids above 300cps.

- Priming Needed: May require priming.

Electromagnetic flowmeter

Provides critical data for process control and monitoring.

Key Features:

- Measurement: Tracks liquid dosing realtime.

- Types: Includes electromagnetic sensor.

- Real-Time Data: Provides immediate feedback for process adjustments.

- High Accuracy: Dosing accuracy below < 1%, ideal for handling differential product parameters like viscosity, varying product supply pressure, and varying temperature.

Applications

- Technical products

- Food and beverages

- Pharmaceutical products

Advantages

- Precision: Accurate dosing and flow measurement.

- Versatility: Handles various fluids and changing conditions.

- Real-Time Monitoring: Enables immediate process adjustments.

Disadvantages

- Installation Cost: Can be high, especially for precise models.

- Complexity: May need specialized knowledge for setup and maintenance.

- Can only handle conductive fluids

- Cannot handle products containing gas or air pockets

Coriolis flowmeter

Measures the mass flow rate of fluids with high accuracy, regardless of changes in temperature, pressure, or viscosity.

Key Features:

- Mass Measurement: Directly measures mass flow rate of liquids even with certain gas concentration inside.

- Types: Includes Coriolis sensors.

- High Accuracy: Precise mass flow data, below <1%.

- Versatile Performance: Effective for almost all products, including those with gases or dissolved substances, such as beer or other foamy products.

Applications

- Food and Beverages

- Pharmaceutical products

- Energy: measures fuel flow and monitoring in combustion processes

Advantages

- Precision: Accurate mass measurement, regardless of fluid properties.

- Real-Time Data: Immediate feedback for process control.

- Versatility: Handles a wide range of fluids, including those with gas or foam.

Disadvantages

- Cost: Higher initial investment compared to regular flow sensors.

- Complexity: More complex installation and maintenance.

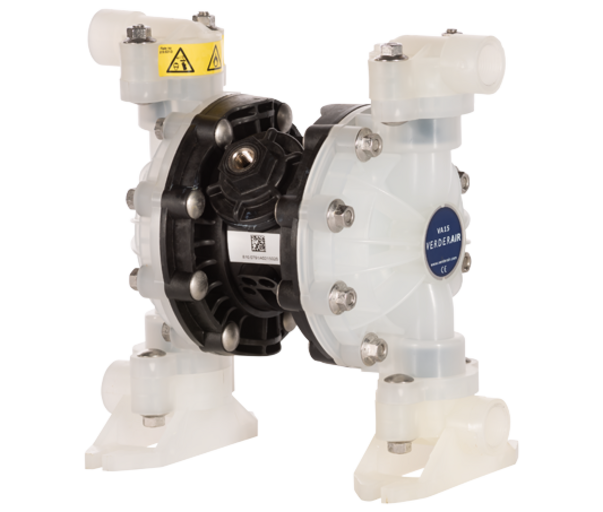

Membrane or Diaphragm pump

A membrane pump, or diaphragm pump, is an easy solution for transferring products, utilizing a flexible membrane to move fluids gently and precisely.

Key features:

- Gentle Handling: Ideal for shear-sensitive products.

- Self-Priming: Handles a variety of fluids, including those with solids.

- Easy Setup: Requires only compressed air.

- Easy to Clean: Compatible with CIP (Clean-in-Place) systems or simple rinsing.

Applications

- Food Processing: Sauces, syrups, and other low to high viscous products, dairy products.

- Beverages: Juice, wine, and other drinks.

- Chemicals: Low to high viscous products, can handle corrosive and abrasive fluids

Advantages

- Continuous flow pumps: good for dosing large volume containers

- Durability: Handles abrasive and corrosive fluids well.

- Versatile: Accommodates a wide range of viscosities.

- Easy setup: only one line of compressed air is required.

Disadvantages

- Noisy and compressed air consumption. Not good for clean room applications.

- Pulsating Flow: May need pulsation dampeners for smooth operation.